KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

Manufacturing technology of Suspended semi submersible vertical turbine pump shock absorber base

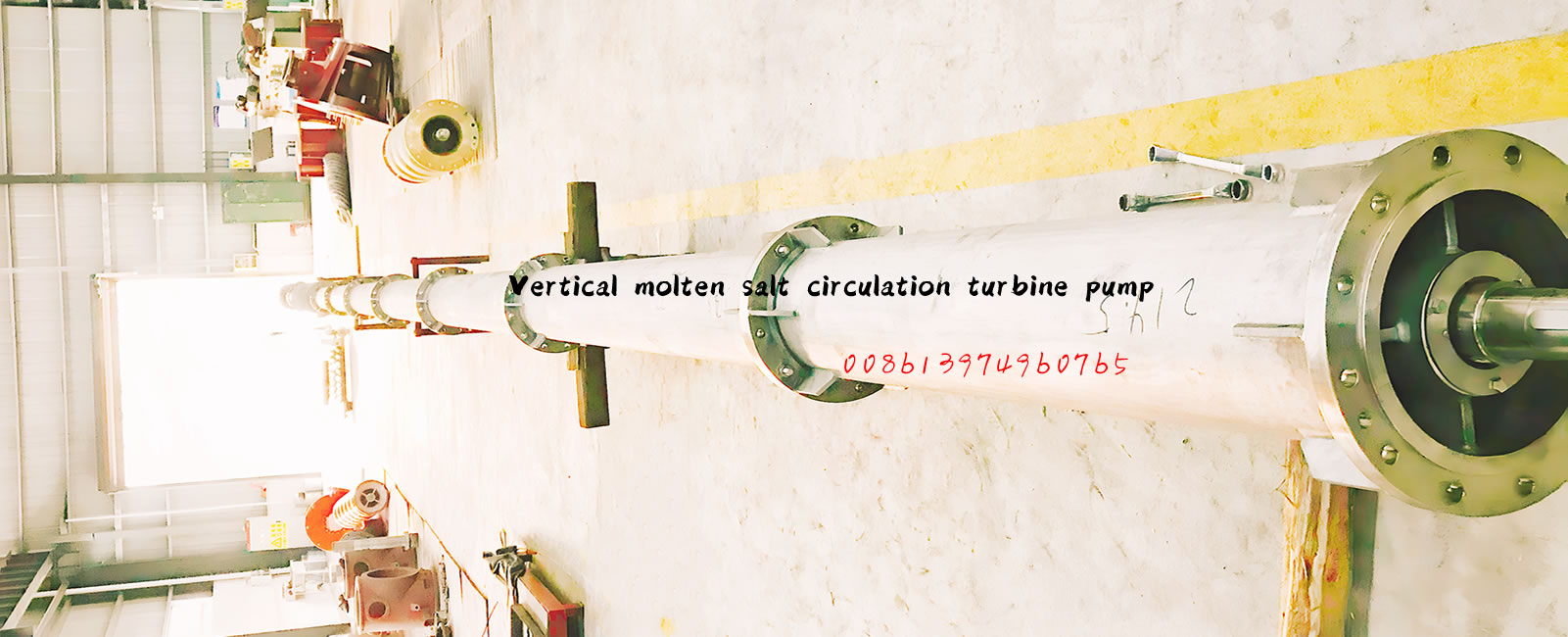

Manufacturing technology for suspension type semi submersible vertical turbine pump shock absorber base, comprising a motor and a motor seat. The bottom of the motor is fixedly connected to the motor seat, and the bottom of the motor seat is fixedly connected to a bearing seat. The bottom of the bearing seat is fixedly connected to a bottom plate, and the bottom of the bearing seat is fixedly connected to a suspension type semi submersible vertical turbine pump. The bottom of the suspension type semi submersible vertical turbine pump penetrates the bottom plate and extends to the bottom of the bottom plate. The top of the bearing seat is fixedly connected to a bearing inside the motor seat. The top of the bearing seat is fixedly connected to a bearing cover, which is fixedly connected to the output end of the motor through a connector. The top of the bottom plate is fixedly connected to a water outlet pipe located on the left side of the motor seat. The bottom of the water pipe runs through the bottom plate and extends to the bottom of the bottom plate, A motor flange is filled between the motor and the motor base. This technical method solves the problem of excessive vibration and inability to meet the needs of traditional suspended semi submersible vertical turbine pumps through the combination of motors, base plates, suspended semi submersible vertical turbine pumps, and outlet pipes.

[Technical Introduction]

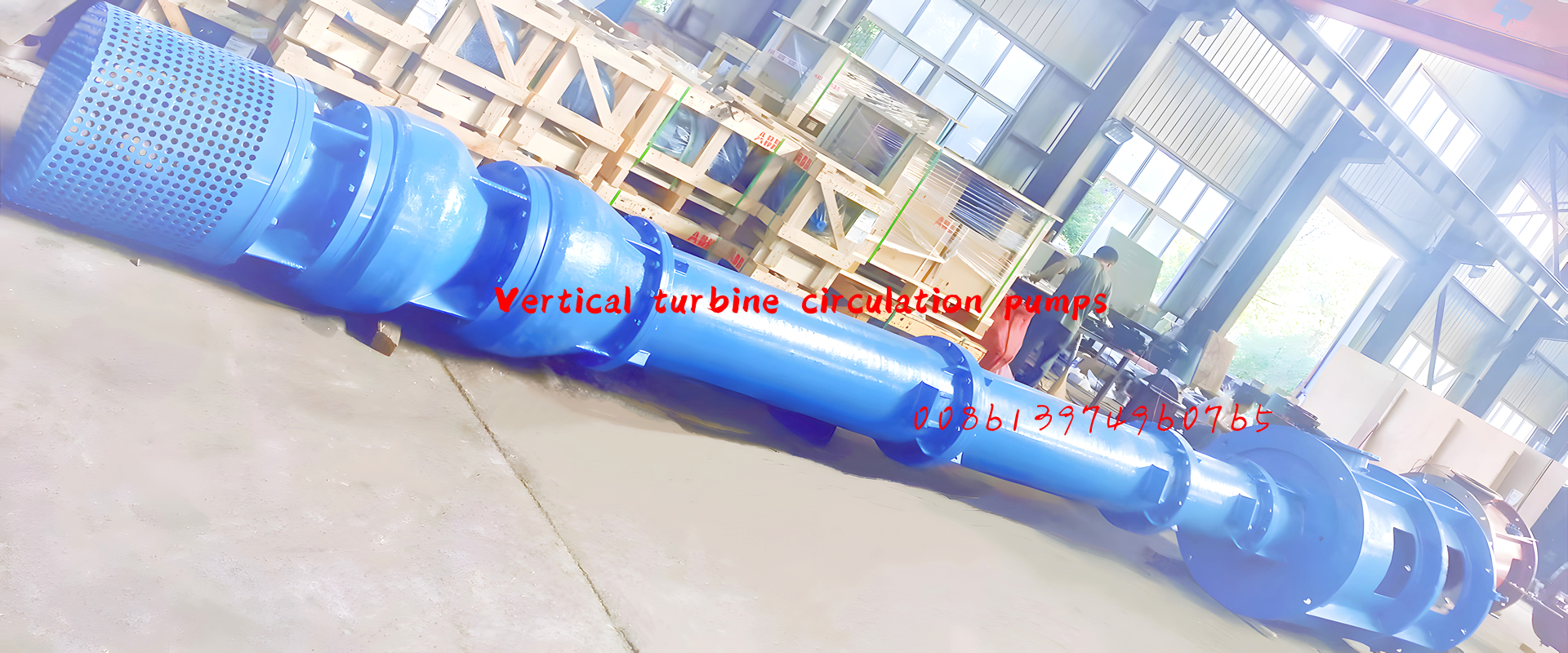

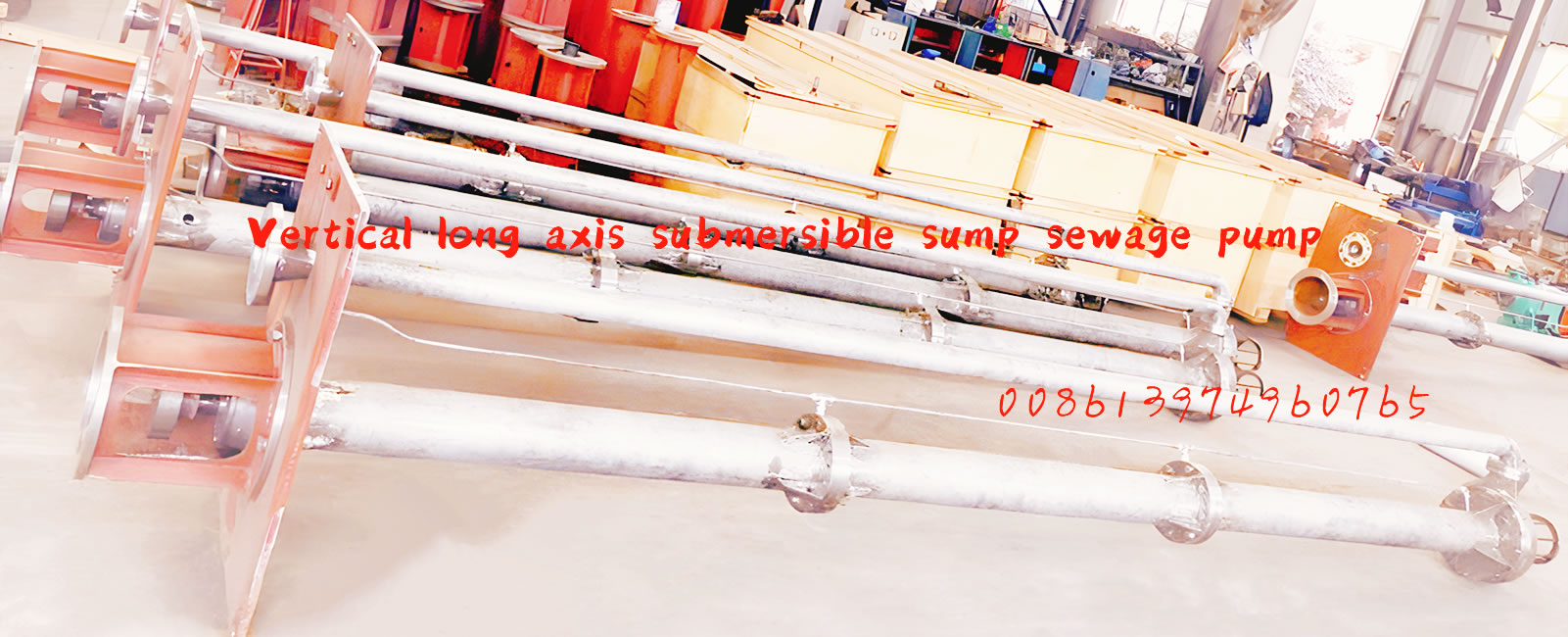

The underwater suspended semi submersible vertical turbine pump has the advantages of high efficiency, energy saving, low pulse, low noise, low vibration, small footprint, stable operation, long service life, easy maintenance, and low selection cost. It is widely used in industries such as thermal power, water conservancy and hydropower, water treatment, papermaking, irrigation water supply, metallurgy, mining, petrochemicals, etc. Power plants have high vibration requirements for water pumps, and many units require the maximum vibration value of the water pump to be less than 0.05 millimeters. Chinese technology CN201771825U mentions a suspended semi submersible vertical turbine pump, which can achieve high temperature and dry wear resistance, but the damping effect is not good and cannot meet the needs of use. Therefore, we propose a suspended semi submersible vertical turbine pump damping base.

Technical implementation ideas

The purpose of this technology is to provide a suspension type semi submersible vertical turbine pump damping base, which has the advantage of good damping effect and solves the problem of excessive vibration during the use of traditional suspension type semi submersible vertical turbine pumps, which cannot meet the needs of use. To achieve the above objectives, the present technology provides the following technical solution: a suspended semi submersible vertical turbine pump shock absorber base, comprising a motor and a motor seat, wherein the bottom of the motor is fixedly connected to the motor seat, the bottom of the motor seat is fixedly connected to a bearing seat, the bottom of the bearing seat is fixedly connected to a bottom plate, the bottom of the bearing seat is fixedly connected to a suspended semi submersible vertical turbine pump, the bottom of the suspended semi submersible vertical turbine pump penetrates the bottom plate and extends to the bottom of the bottom plate, the top of the bearing seat is fixedly connected to a bearing located inside the motor seat, and the top of the bearing is fixedly connected to a bearing cover. The bearing cover is fixedly connected to the output end of the motor through a connector, and the top of the bottom plate is located at the top of the motor. There is a fixed water outlet pipe connected to the left side of the seat, The bottom of the water outlet pipe runs through the bottom plate and extends to the bottom of the bottom plate, and a motor flange is filled between the motor and the motor base. Preferably, the motor flange is fixedly connected to the motor seat through a first connecting bolt, and the base plate is fixedly connected to the bearing seat through a second connecting bolt. Preferably, the suspended semi submersible vertical turbine pump is fixedly connected to the bearing seat through a third connecting bolt, and a skeleton seal is provided between the suspended semi submersible vertical turbine pump and the bearing seat. Preferably, the motor seat is fixedly connected to the bearing seat through a fourth connecting bolt.

Suspended semi submersible vertical turbine pump shock absorber base

[Technical Key Points]

A suspension type semi submersible vertical turbine pump shock absorber base, comprising a motor (1) and a motor seat (2), characterized in that: the bottom of the motor (1) is fixedly connected to the motor seat (2), the bottom of the motor seat (2) is fixedly connected to the bearing seat (3), the bottom of the bearing seat (3) is fixedly connected to the bottom plate (4), the bottom of the bearing seat (3) is fixedly connected to the suspension type semi submersible vertical turbine pump (5), the bottom of the suspension type semi submersible vertical turbine pump (5) penetrates the bottom plate (4) and extends to the bottom of the bottom plate (4), and the top of the bearing seat (3) is fixed inside the motor seat (2). A bearing (6) is connected, and a bearing cover (7) is fixedly connected to the top of the bearing (6). The bearing cover (7) is fixedly connected to the output end of the motor (1) through a connector (8). A water outlet pipe (9) is fixedly connected to the top of the bottom plate (4) and located on the left side of the motor seat (2) The bottom of the motor (1) runs through the bottom plate (4) and extends to the bottom of the bottom plate (4), and a motor flange (10) is filled between the motor (1) and the motor seat (2).